home / product / FBQ Multi-purpose Chamber Furnace

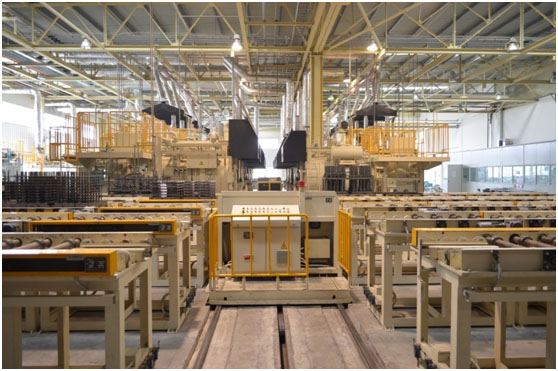

FBQ Multi-purpose Chamber Furnace

8/ 30, 2017

The load of FBQ Multi-purpose Chamber Furnace is heavy which is suitable for high capacity and heavy load occasion, unique back driving device and prechamber fast nitrogen repressing will ensure the reliablility and safety of equipment. Thesutomaticity of equipment is high,the load is heavy and the maintenance is easy.

Advantages of prechamber:

● the front door of gas tight will be compressed by double –cylinder which has safe and reliable seal.

● prechamber door, insulated door, lifter will be dirven by cylinder, when the power is out or accident happens, it can ensure the product quality and equipment safety.

● it equipped with strong quenching ability, and high volume quenching oil tank, the speed for heating and cooling will be faster;it has independent bilateral agitating system, and the agitating speed can be frequency conversion adjusted, the uniformity of oil temperature is good. These will ensure the cooling consistency and uniformity of the products.

● the nitrogen can be charged rapidly in case the front door may emerge the dangerous negative pressure.

● the prechamber can be as charging room and dischanging room, and combine the gas cooling with oil quenchinig tank, the lifter in prechamber will use the bilayer structure. When the workpieces on upper layer are cooling, the sublayer will be charging at the same time. This will save amount of time,so the use ratio of furnace room is high.(optional)

● a agitating fan is equipped in prechamber which can control the cooling speed according to process,and can monitor the thermocouple and record the cooling process(optional).

Advantages of heating chamber:

● the charge and discharge of workpieces will use the way of back drive which will place on the back of heating chamber(there is no driving structure in prechamber,the structure is simple and the failure rate is low), the time that the propelling structure stops in heating chamber is short and has no defibrator process damage.

● the support on furnace hearth will use the high class heat resistant steel roller which will effectively reduce load and the friction on furnace hearth, especially for the heavy load.

● an agitator is equipped on the top of heating room.The thermal chamber will use the structure of circular furnace without muffle,the structure behaviour is strong, the service life is long; it has good temperature and atmosphere uniformity,maintenance is simple and the cost is low.

●Radiant tube will arrange on the two sides and the bottom of heating chamber according to the hot-zone distribution requirement, while using SCR/PID to control. So the temperature uniformity is good.

●Equally effective area of space conditions, radiating area of circular furnace is 17% less than square furnace which will save huge amounts of energy.

●The aging time of the chamber is 1/3~1/6 less than conventional furnace type, it will have less gas consumption and save costs.

● multipurpose structure style which can choose whether electrical heating type or gas heating type.

● program storage.

●Equipment autoprogramming is high.

●Configure ethernet to achieve programming, monitoring,reciving data records by internet(optional).

● TFT colour large screen integrating controller which can control, monitor,and record.(optional)

● PC online carbonitriding layer control system(optional).

control cabinet:

● the accuracy of temperature control and process control is high.

● the programmable control will be used during all the motor process.

● set simulation control panel and touch operation screen,equipment visualization,the state can be clear at a glance.

FBQ Multi-purpose Chamber Furnace suitable heat treatment processes:

● carburizing

● carbonitriding

● quenching,normalizing,annealing under protection atmosphere

● double heat quenching

● carbon restoration